Horse Totem Machined by SMTCL Engineers | High-Precision CNC Processing Showcase

When the craftsmen pick up the "digital brush", watch how the general-purpose technical machine tools bring to life the "legend of the Year of the Horse"!

Horses symbolize speed and strength, and represent achieving success at once. On the occasion of the Lantern Festival, the technicians of General Technology Machine Tools no longer confined themselves to the roar of the workshop and the flashing of codes. They transformed into "digital artists" and presented a unique "Painting Horses with Brushstrokes, Transmitting Craftsmanship through Digital Means" theme calligraphy and painting exhibition.

When "industrial software" meets "traditional zodiac signs", this is not an ordinary calligraphy and painting exhibition. The creators here are engineers and technical experts who usually deal with steel, codes, and precise drawings. Their "brushes" are precise and sharp professional industrial software; their "paper" is the vast and boundless three-dimensional models and simulation data. They transformed their profound mechanical expertise into dynamic digital art, giving the cold machines warmth and giving the rigorous data a soul. Let's witness the perfect fusion of technology and tradition together, and feel the craftsmanship and romance that come from the industrial frontline!

Form: SW three-dimensional modeling

The steed gallops forward, leading the way into the future. Behind the precise design lies the unwavering pursuit of the General Technology machine tool workers for the pinnacle of technology.

SMTCL FANUC 10000rpm Y axis travel 550mm VMC850Q 4 Axis Vertical Machining Center with Turntable

Form: Aluminum sculpture ornaments

When the cold and stern texture of metal meets the passionate soul of art, a dialogue of strength and softness begins. Every precise and sharp cutting mark is an unspoken badge of the artisan's spirit.

With digital technology as its wings, it helps the steeds soar high; with innovative thinking as its soul, it creates masterpieces that will last forever. The technicians of General Technology are galloping and striving ahead in the vast realm of high-end equipment manufacturing, determined to realize the grand blueprint of "Made in China" through practical actions!

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

SMTCL best-selling product - GMC2040RV-A gantry machining center

GMC2040RV-A Gantry Machine Tool: A New Hit Model Launched

The new hit GMC2040RV-A gantry machine tool, manufactured by the Gantry Boring and Milling Assembly Branch of CNC Machine Tool Group Shenyang Machine Tool Co., Ltd. under China General Technology (Group) Holding, Ltd. (Genertec), has been officially launched into the market. This marks the company's in-depth expansion of the "hit product assault campaign" into the core track of gantry products, powerfully kicking off a "good start" for the first quarter of the new year.

As a strategic gantry product built for the pillar industries of the national economy and large-scale high-efficiency manufacturing scenarios, the GMC2040RV-A features "modularization, high efficiency and fast delivery" as its core selling points. Relying on the integrated collaboration mechanism of "production, sales, R&D and application", the company has systematically integrated resources in design, manufacturing, supply chain and services. While ensuring the stable performance and high-efficiency processing of the whole machine, it has significantly reduced the comprehensive use cost for customers. The core commitments to customers include a 20-day delivery period for regular configured orders, an extended 2-year warranty for the whole machine, and a safe inventory system of "in-stock goods for worry-free delivery". These commitments aim to make customers more assured in equipment investment and more relaxed in production capacity planning. This is not only a business logic of "high quality at a favorable price", but also a solid starting point for building long-term collaborative relationships with customers.

Building a hit single gantry product is by no means a simple product iteration, but a strategic fulcrum for the company to break through and gain an edge in the fierce market competition. In 2025, Genertec Shenyang Machine Tool listed the upgrade of gantry products as a key assault task. Company leaders led teams to conduct in-depth investigations at key customers' sites, competitor production lines and international exhibitions, promoting the formation of a synergy covering the entire industrial chain and effectively connecting market demand with manufacturing response: transforming customers' feedback into product definitions, actual working conditions into iteration basis, and manufacturing capabilities into delivery commitments. Particularly crucially, the GMC2040RV-A has further strengthened the independent supply of core functional components—key components such as accessory heads are independently R&D and manufactured. Through design optimization and supply chain collaboration, the company has achieved significant cost reduction, efficiency improvement and stable delivery.

SMTCL Heavy CNC Gantry Machining Center GMC2040RV Gantry CNC Milling and Boring Center Machine

This iteration goes far beyond the product itself and has become a vivid practice of Genertec Shenyang Machine Tool's philosophy of "growing together with customers". The company is moving from "delivering equipment" to "co-building a manufacturing ecosystem". Relying on its hit product matrix, it provides customers with a full-life-cycle service based on the certainty of equipment—ranging from production line planning and production capacity layout to software integration and resource collaboration. Every demand feedback from customers serves as a starting point for the product iteration and upgrade of Genertec Shenyang Machine Tool; every leap in the company's capabilities injects new development momentum into the long-term development of customers. In this mutual pursuit, hit products continue to emerge and the ecosystem naturally expands and grows stronger.

"The successful launch of the GMC2040RV-A marks that we are proactively defining product value and leading the new development direction of the industry with our unique technological advantages and superior manufacturing capabilities compared with competitors," said Chen Tao, Factory Director of the Gantry Boring and Milling Assembly Branch.

Towards the 15th Five-Year Plan period, Genertec Shenyang Machine Tool will further focus on its core business of high-end equipment manufacturing, concentrate resources to build core competitiveness, and continuously improve its hit product matrix. It will promote the formation of a new development pattern of "hit products leading, full product range linkage", consolidate the product foundation for high-quality development with replicable "hit product" models and comprehensively improved operating results, and firmly take every step forward in high-end intelligent manufacturing.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

What are the Process Characteristics and Advantages of Vertical Machining Centers?

What are the Process Characteristics and Advantages of Vertical Machining Centers?

A vertical machining center is an advanced CNC machine tool with distinctive process characteristics and remarkable advantages, playing a pivotal role in modern manufacturing industry. This article elaborates on the process characteristics and advantages of SMTCL (Shenyang Machine Tool Co., Ltd.) vertical machining centers.

I. Process Characteristics

1. Vertical structure The machine tool is designed with a vertical structure, where the worktable is fixed on the column and the cutting tool moves in the vertical direction. This structure ensures greater stability and higher rigidity during the machining process, making it suitable for processing workpieces with high precision and strict requirements.

2. Multi-axis linkage Vertical machining centers are usually equipped with a multi-axis linkage system, which enables simultaneous movement of multiple axes, improving machining efficiency and precision. Multi-axis linkage simplifies the machining of complex curved surfaces and allows the completion of multi-sided machining in one operation.

3. High speed and high precision Vertical machining centers feature high speed and high precision, enabling fast and accurate machining. They are ideal for processing precision components and molds with stringent accuracy requirements.

4. High degree of automation Equipped with automated devices such as an automatic tool change system and an automatic measurement system, vertical machining centers realize automated production, which boosts production efficiency and reduces labor costs.

5. Strong flexibility Vertical machining centers can be configured with different machining processes and parameters according to processing requirements, boasting high flexibility and being suitable for the production of multiple varieties in small batches.

SMTCL 10000rpm FANUC 3 Axis Vertical Machining Center VMC850Q 4 Axis CNC Milling Machine With Turntable

II.Advantages

1. High efficiency Adopting a vertical structure and a multi-axis linkage system, vertical machining centers achieve high-speed and high-precision machining, which improves production efficiency and shortens the machining cycle.

2.High precision With a sophisticated control system and a stable structural design, vertical machining centers realize high-precision machining, ensuring product quality and machining accuracy.

3.Multifunctionality They can perform a variety of machining operations including milling, drilling, boring and tapping, with strong multifunctionality to meet diverse processing needs.

4.Energy saving and environmental protection SMTCL vertical machining centers adopt an advanced energy-saving control system and an eco-friendly design concept, featuring low energy consumption and little environmental pollution, which complies with the sustainable development requirements of modern manufacturing industry.

4.Ease of operation Vertical machining centers are usually equipped with a user-friendly man-machine interface and an intelligent operating system, which are simple to operate, easy to learn and use, thus improving production and work efficiency.

In summary, SMTCL vertical machining centers possess process characteristics such as a vertical structure, multi-axis linkage, high speed and high precision, a high degree of automation and strong flexibility, as well as advantages including high efficiency, high precision, multifunctionality, energy saving and environmental protection, and ease of operation. As an indispensable key equipment in modern manufacturing industry, it is of great significance for enterprises to improve production efficiency and product quality.

We focus on a variety of vertical machining centers. Different machines have different parameters that can meet the processing requirements of various workpieces. We offer a one-stop solution. Click "Contact Us" to get personalized service.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

New Addition to the "Blockbuster" Matrix! VMC850Q-A Sets a New Quality Standard

As the Start of Spring ushers in a new phase of growth and renewal, on February 4th, Shenyang Machine Tool under China General Technology (Group) Holding Co., Ltd. officially launched the marketing campaign for its second blockbuster product - the VMC850Q-A vertical machining center. Building on the remarkable market success of the iV85 that secured a flying start for the year, the VMC850Q-A, featuring "high-precision forming and highly adaptable layout", has ignited the second battle of the "blockbuster product assault campaign". This move fully demonstrates the company's firm determination to forge blockbuster products with superior quality and seize market share with these competitive offerings.

The VMC850Q, a universal vertical machining center popular across the country, has already established a mature and stable market reputation. Based on this solid foundation, the VMC850Q-A, manufactured by the Vertical Machining Center Assembly Branch, has undergone a systematic iteration and upgrade: its core functional components have been optimized and enhanced, effectively improving the overall reliability of the machine; its highly adaptable layout is fully compatible with automatic production lines, providing precise services to customers in the traditional automotive and new energy industries. As a flagship model of the Q series, the VMC850Q-A focuses on the domestic mid-end market and meets customers' core demand for equipment that remains "as good as new after long-term use and operates without worries". It forms a clear hierarchical product system with the iV85, which prioritizes extreme cost performance - the iV85 serves the pragmatic application scenarios in the general machinery industry where "sufficiency is enough", while the VMC850Q-A targets niche sectors such as traditional automotive and new energy, delivering an "exquisite and refined" quality experience, and is particularly suitable for the automatic line production scenarios of leading industry customers. In the future, the company will form a hierarchical product matrix with the iV85 as the foundation, the Q series as the backbone, the H series for upward breakthroughs, and the P series as the benchmark, effectively enhancing its market pricing power and brand influence.

Sang Huiqing, a Technician Expert of Central Enterprises, is not only a frontline assembly backbone of the Vertical Machining Center Assembly Branch but also a promotion ambassador for this blockbuster product launch. In his view, the most proud breakthrough of the vertical machining center series products in 2026 is the complete solution to the long-standing industry problem of "tool marks". For a long time, tool marks have been regarded as a common issue with vertical machining center products, accepted by customers as a normal phenomenon, and mostly explained by the industry as such. Today, "Farewell to Tool Marks" is prominently printed on the product promotion posters of the VMC850Q-A - this is not just a marketing slogan, but a reflection of the confidence stemming from the overall quality leap of the entire product line. Li Shibo, Deputy Factory Director of the Vertical Machining Center Assembly Branch, stated: "The fact that customers do not raise a demand does not mean we can neglect it. True quality is the value that customers can see at a glance and feel immediately upon use."

What to Do for CNC Machine Tool Maintenance During Spring Festival?

Guide to Maintenance of Machine Tools during Spring Festival

As the Spring Festival holiday approaches, machine tools will be idle for extended periods. To ensure stable operation during the break, timely troubleshooting and diagnostics should be conducted beforehand. This not only guarantees normal machine performance and extends service life but also enhances industrial efficiency and safeguards corporate profitability. SMTCL has compiled essential maintenance guidelines for machine tools during the holiday season.

SMTCL 4 Axis CNC Milling Machine VMC1000Q High precision Aluminum Alloy Processing Vertical Machining Center

Precautions for Year-End Shutdown

Cleaning/Rust-proofing/Moisture-proofing/Rodent-proofing

1. Clean the machine tool interior, worktable area, front and rear door slides, tool magazine interior, and the tool changer arm of chips.

2. Clean the chips from the external chip breaker.

3. Remove the tool from the spindle and clean the spindle end face, inner taper hole, and accessory head.

4. Remove, clean, and reinstall the air conditioning filter and oil cooler filter in the electrical control box.

Return to Position

1. Move the Y-axis of the CNC machine tool to the midpoint and reset the Z-axis to zero.

2. Turn off the main power switch of the machine tool, the transformer inlet switch, and the air supply.

Post-New Year Power-On Precautions

1. Inspection of machine tool power supply and air supply. Confirm the stability of voltage and air pressure, and connect the air hose after verifying the air quality (free from water and dust).

2. Inspect the electrical cabinet. Open the cabinet to confirm no condensation, no debris, and no signs of wiring damage.

3. Inspection of lubrication and hydraulic systems. Check whether the oil quality and liquid levels in all lubrication and hydraulic systems are normal, confirm the availability of lubricating oil and hydraulic oil coolant, and ensure timely replenishment.

6. Warm-up. After powering on the machine tool, release the emergency stop and allow the electrical components to warm up for 30 minutes.

7. Preheating. After warm-up, run idle for 1 hour, then slowly reciprocate each servo shaft for thorough lubrication. Start low-speed rotation of the spindle, gradually increasing both speed and rotation rate.

SMTCL VMC850Q 3 Axis Vertical Machining Center 4 Axis CNC Milling Machine With Turntable

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Why Choose Shenyang Machine Tool's Vertical Machining Center?

Shenyang Machine Tool's vertical machining center (VMC) stands out with four core configurations: spindle, tool magazine, guide rail, and CNC system. Boasting high rigidity, high precision, and high efficiency, it is well-suited for various industrial processing needs such as auto parts and precision molds, making it an excellent choice for industrial production.

SMTCL VMC850Q 3 Axis Vertical Machining Center 4 Axis CNC Milling Machine With Turntable

1. Premium Spindle for Stable Precision

The spindle assembly of Shenyang's VMC selects original Taiwanese components, paired with P4-class special spindle bearings. Through constant-temperature assembly and dynamic balance calibration, it achieves stepless speed regulation within the speed range and supports rigid tapping function. With strong cutting force and stable operation, it guarantees machining precision from the source.

2. Robot-Type Tool Magazine for Efficient Production

Equipped with a robot-type tool magazine driven and positioned by a roller cam mechanism, the spindle enables fast and noise-free tool changes with precise and smooth movements. It effectively shortens processing cycles, greatly improves workshop production efficiency, and is ideal for mass processing scenarios.

3. Imported Linear Guide Rail for Long-Lasting Stability

Featuring imported linear guide rails, the VMC has low dynamic and static friction, realizing stable operation with no crawling at low speeds and low vibration at high speeds. Combined with a centralized automatic thin oil lubrication system, it reduces friction loss, ensures high positioning accuracy, and extends the service life of the guide rails.

4. High-End FANUC CNC System for Easy Operation

Standard with the high-end FANUC Oi series CNC system, it adopts a fully digital structure with strong processing capability. It can achieve precise multi-axis control, offering convenient operation and excellent compatibility. Even complex processing procedures can be completed efficiently, balancing operational experience and processing results.

Strict Factory Inspection for Reliability

All four core components of Shenyang's VMC are optimized by professional Pro/E and Ansys design, ensuring outstanding overall rigidity and stability.

Before delivery, strict inspections are conducted under standard environmental conditions (20℃±5℃, humidity 40%-60%): spindle rigidity, tool magazine changing accuracy, guide rail lubrication performance, and CNC system stability are tested, while safety indicators such as protective devices and structural strength are verified simultaneously.

Why SMTCL?

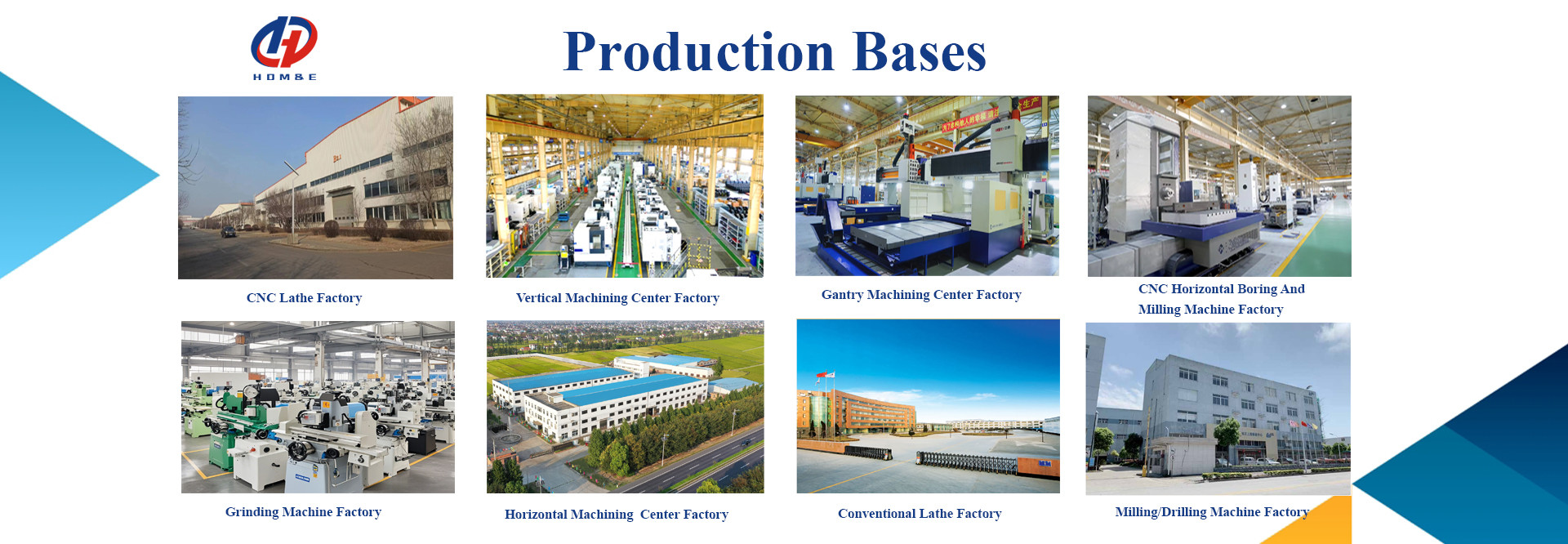

Shenyang Machine Tool is subordinate to GT Group, with its headquarters located in Shenyang Economic and Technological Development Zone, it has three industrial parks, namely CNC machine tool park, Xihe Large/heavy-duty machine tool park and Yinfeng casting park, covering an area of 1.24 million square meters and employing nearly 5,000 on-the-job staff.

SMTCL 4 Axis CNC Milling Machine VMC1000Q High precision Aluminum Alloy Processing Vertical Machining Center

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Celebrate the New Year! Limited-time sale of the best-selling product iV85!

Product Description:

SMTCL Economical GSK Controller CNC Milling Machine IV85 Vertical Machining Center

The iV85 product is mainly used for processing parts in industries such as automobiles, motorcycles, and agricultural machinery. It can meet the requirements of efficient and large-scale processing. The entire machine adopts a vertical frame layout. The human-shaped columns are fixed on the bed, and the main spindle box moves up and down along the columns (in the Z direction), the slide seat moves longitudinally along the bed (in the Y direction), and the worktable moves laterally along the slide seat (in the X direction). The machine has a large load-bearing capacity, high rigidity, low dynamic and static friction, high sensitivity, small high-speed vibration, low-speed no crawling, high positioning accuracy, and excellent servo drive performance. The modular design, high-performance customized configuration, can continuously complete milling, drilling, reaming, tapping, boring, tapping and other operations, as well as two-dimensional and three-dimensional curved surface and inclined surface precise processing, achieving better economic benefits.

Ultra-high value for money, high-quality forming vertical machining center

PRODUCT SPECIFICATIONS:

We focus on a variety of vertical machining centers. Different machines have different parameters that can meet the processing requirements of various workpieces. We offer a one-stop solution. Click "Contact Us" to get personalized service.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Good News: Shenyang Machine Tool Co., Ltd. has been awarded the title of "Zero-Carbon" Factory in Shenyang City

Recently, the Shenyang Municipal Bureau of Industry and Information Technology announced the list of the second batch of "zero-carbon" factories. Shenyang Machine Tool Co., Ltd. was successfully included and is the only machine tool manufacturing enterprise among the eight units in this batch.

This selection was jointly organized by the Municipal Bureau of Industry and Information Technology, the Municipal Development and Reform Commission, and the Municipal Ecology and Environment Bureau. It was determined through procedures such as enterprise application, formal review, expert evaluation, and on-site verification. The company has systematically sorted out 13 practical achievements in areas such as renewable energy substitution, technological transformation and upgrading, energy conservation and carbon reduction, and green system construction, providing regional enterprises with referenceable carbon reduction paths.

At present, the company has established 2 national-level green factories, 1 provincial-level green factory, 1 provincial-level green supply chain management enterprise, 3 provincial-level green design products, 2 municipal-level "zero-waste" enterprises, and has added 1 municipal-level "zero-carbon" enterprise. The green manufacturing system is continuously improving.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

SMTCL VMU30H 5-Axis Machining Center: High-Precision and High-Efficiency Machining

In the field of high-end precision manufacturing, 5-axis machining centers are hailed as the "jewel in the crown", whose performance directly determines the processing quality and production efficiency of complex and irregular parts. As a leader in China's machine tool industry, China General Technology Shenyang Machine Tool (SMTCL) has launched the VMU30H vertical 5-axis machining center. With its core advantages of high rigidity, high speed and high precision, it has become the equipment of choice in industries such as 3C electronics, medical equipment and precision molds. Furthermore, it has broken international monopolies with independent innovation technologies, redefining the performance standards of domestic 5-axis machine tools.

Core of VMU30H: Tailor-Made for Complex Machining Scenarios

The VMU30H is a high-efficiency vertical 5-axis machining center developed by Shenyang Machine Tool for the processing of small and medium-sized complex parts. The whole machine adopts modular design and precision manufacturing technology, achieving a breakthrough in performance within a limited space. Its core parameters and structural design are fully adapted to the high-efficiency production needs of modern manufacturing industry:

Tailored for small-to-medium complex parts, the VMU30H features modular design and precision craftsmanship. Key specs:

Worktable: Φ320mm, max load 70kg; X/Y/Z strokes: 400/500/300mm

HSK-E40 spindle: 30,000rpm, 11kW (S6 mode); Siemens CNC system

20-tool magazine: 3s tool change; Rapid feed: 18m/min; 1G linear acceleration

Three Core Advantages: Redefining the Performance Standards of Domestic 5-Axis Machine Tools

The VMU30H stands out not only due to its accurate market positioning, but also benefits from Shenyang Machine Tool's long-term accumulation in core technologies. Its advantages are concentrated in three dimensions: precision, efficiency and stability, and each performance is supported by solid technologies:

1. Micron-Level Precision

Passes ISO 230-10 S-test: Linear positioning accuracy

what is TPX horizontal borling machine?

Product Description:

The TPX series horizontal milling and boring machines are based ona classic design, suitable for rough and finished boring, capable ofmilling large and box type components. They excel at inner hold boring.cylindrical turning and grooving by radial feed of facing plate. A 4x90 optical positioning device allows for machining accuracy when turninglarge pieces. The precision digital read out measurement system sensures accuracy of coordinates and lineation.

DRO Horizontal Boring and Milling Machine TPX6111B Manual Heavy Duty Horizontal Milling Boring Machine

The core advantages are as follows:

1. Ultra-high rigidity + stable durability, no pressure in heavy-duty cutting

The machine body is made of integral cast iron casting and optimized by finite element design, featuring strong structural rigidity and outstanding shock resistance. It can easily handle high-intensity and large-volume cutting processing (such as deep hole boring of machine tool beds and box-type parts).

The core components (spindle, guide rail, lead screw) are all independently developed by Shenyang Machine Tool and processed with precision grinding technology. The long-term continuous operation failure rate is less than 2%, and the service life exceeds 15 years, reducing the long-term usage cost for customers.

2. High-precision processing to meet strict tolerance requirements

Equipped with a precision ball screw and servo drive system, the positioning accuracy is ≤0.02mm, the repeat positioning accuracy is ≤0.01mm, and the surface roughness of the processed surface can reach Ra 1.6μm, comparable to imported equipment.

The main shaft adopts constant temperature control technology, effectively offsetting the influence of cutting temperature rise, ensuring the consistency of batch processing, and increasing the product qualification rate to over 99.8%.

3. Multi-functional integration, suitable for processing needs in various scenarios

It supports compound processing such as boring, milling, drilling, tapping and reaming, and can complete multi-process processing of complex parts in one stop, reducing equipment switching time and increasing production efficiency by 30%.

It can be optionally equipped with a CNC rotary table and an automatic tool changer system (ATC) to achieve automated continuous processing, suitable for medium and small batch multi-variety production, and flexibly respond to order changes.

4. Convenient operation and humanized design lower the threshold for use

Equipped with a bilingual numerical control system in Chinese and English (optional Siemens, Fanuc or domestic high-end systems), the interface is intuitive, programming is simple, and even beginners can quickly get started.

The layout of the machine tool is reasonable, facilitating the hoisting of workpieces, tool changing and daily maintenance. The operating space is spacious, reducing the labor intensity of workers.

5. High cost performance + customized adaptation, meeting the essential needs of the industry

The price is only 60% to 70% of that of imported brands with the same configuration (such as Coburg from Germany and Toshiba from Japan), and the procurement cost can be controlled without sacrificing precision and stability.

We can customize the spindle speed, stroke and accessory configuration according to the industry requirements of customers (such as construction machinery, wind power components, mold processing), and provide exclusive processing solutions.

6. Domestic benchmark + perfect after-sales service, no worries when purchasing

With 60 years of experience in machine tool manufacturing, Shenyang Machine Tool's TPX series has been proven by the market. It has over 20,000 domestic customers, enjoys a solid reputation and has an abundant supply of spare parts.

PLC Horizontal Boring and Milling Machine TPX6113 Heavy Horizontal Milling Boring Machine With Digital

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Successful Export of Shenyang Machine Tool CAK100285 to Russia: High-Efficiency Equipment and Professional Service Win Customer Acclaim

As a core product of Shenyang Machine Tool, the CAK100285 CNC lathe has become a game-changer for Russian manufacturers facing Western sanctions. With its reliable performance, cost-effectiveness, and tailored support, this machine has won high praise from Russian customers—proving that Chinese high-end machine tools are a trustworthy alternative in the global market.

In the field of industrial equipment, the Shenyang Machine Tool CAK100285 model has always been highly regarded by global customers for its exceptional performance and reliability.

Recently, we successfully exported this high-performance machine tool to Russia and received positive feedback from the customer.

About Shenyang Machine Tool CAK100285: A High-Power Tool for Industrial Manufacturing

The Shenyang Machine Tool CAK100285 is a high-precision CNC lathe designed for heavy-duty and high-efficiency machining, making it ideal for key industries such as aerospace, automotive manufacturing, mechanical parts processing, and military component production.

Core Product Advantages:

High Precision and Stability: Equipped with an advanced CNC system, it ensures machining accuracy with an error of less than 0.01mm, making it suitable for complex component production.

High-Efficiency Production Capacity: With an automatic tool changer and high-speed spindle, it significantly improves production efficiency, making it ideal for large-volume orders.

Cost-Effectiveness: Priced 30% lower than comparable German and Japanese models, the CAK100285 offers exceptional value while meeting industrial-grade precision requirements. It helps Russian manufacturers reduce production costs without compromising quality.

Wide Applicability: It can be applied to various industries such as automotive, aerospace, and mold manufacturing, meeting diverse machining needs.

Successful Export to Russia: Localized Service and Customer Satisfaction

This export case to Russia fully demonstrates Shenyang Machine Tool's professional capabilities in global operations.

The Russian customer is a company specializing in precision component manufacturing. While searching for cost-effective equipment, they found us through Google search for "Shenyang Machine Tool CAK100285 Russian supplier."

From the initial inquiry to the transaction, the entire process was efficient and smooth, and the customer expressed high satisfaction with the equipment's performance and service.

After receiving the equipment, the customer quickly completed the installation and put it into production.

They specifically mentioned that the stability and ease of use of the CAK100285 exceeded expectations, helping them increase production capacity in a short time.

More importantly, our team, addressing the specific needs of the Russian market, specially compiled a detailed user manual for this equipment, covering operation guidelines, maintenance tips, and troubleshooting solutions.

This manual not only helped the customer quickly master equipment operation but also reflected our "customer-centric" service philosophy.

The customer feedback stated: "This manual is very practical and saved us a lot of time during installation and use. Shenyang Machine Tool's professional team has filled us with confidence for future cooperation."

Conclusion: Choose Shenyang Machine Tool for a Win-Win Partnership in the Russian Market

If you are also looking for reliable machine tool equipment, welcome to visit our independent website for more information. Shenyang Machine Tool will help you achieve efficient production and business growth!

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

SMTCL Efficient solution for automatic machining and inspection of new energy motor shafts

SMTCL A625 New Energy Motor Shaft Automated Production Line Processing and Inspection Unit

Product Description:

SMTCL Efficient solution for automatic machining and inspection of new energy motor shafts

The new energy motor shaft automated processing and inspection unit is composed of an HTC40P high-precision horizontal CNC lathe, a VMC1100P high-performance vertical machining center, a domestic 6-axis joint robot, and a double-station exchange pallet type silo. It can perform automatic processing and inspection without human intervention, enabling one person to manage multiple sets of automated units. Effectively save labor costs. Meanwhile, the automation unit realizes the rapid production change of motor shafts of different specifications through modular design. The overall layout adopts an L-shaped design, featuring a compact structure and the optimal running path for the robot, enabling efficient processing of parts.

Technical advantages: The M45 type shaft parts measuring instrument equipped adopts the OPC-UA standard communication protocol, which can realize the mapping of the instrument in the virtual space and be connected to the intelligent factory, ensuring the accuracy of the detection and the real-time transmission of data. Meanwhile, the collaborative operation between robots and various processing equipment as well as silos has enabled the automatic handling and loading/unloading of materials, enhancing the degree of automation and continuity of production.

Product Features:

1,Full-process automated closed-loop, integrating 12 processes + robot loading/unloading, with 30% efficiency increase, suitable for mass production.

2,Micron-level precision control, featuring laser online inspection + real-time compensation, with tolerance ≤0.005mm, meeting high-speed dynamic balance requirements of motor shafts.

3,Multi-process combined machining, achieving full-structure machining in one clamping, 30-minute quick changeover, compatible with multiple specifications of φ50-200mm.

Product display:

Product video:

Click to go directly to the video and see how SMTCL A625 achieves full automation in shaft machining!

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Good News: Shenyang Machine Tool Yinfeng Foundry Co., Ltd. has been awarded the title of Provincial Green Factory

Recently, the Department of Industry and Information Technology of Liaoning Province has publicized the list of provincial green manufacturing for 2025 (the 10th batch), and Shenyang Machine Tool Yinfeng Foundry Co., Ltd. has been selected as a "Green Factory of Liaoning Province".

The foundry industry is a traditional high energy-consuming and high-emission field. In recent years, Shenyang Machine Tool Yinfeng Casting Co., Ltd. has systematically advanced its green and low-carbon transformation. On the one hand, it has increased investment in environmental protection facilities, implemented full-process energy-saving renovations, and continuously reduced energy consumption per unit of product. On the other hand, we have improved the environmental and energy management system, strictly implemented the classification treatment and standard discharge of waste gas, waste water and solid waste, and have obtained multiple certifications such as ISO 14001 environmental management system and ISO 50001 energy management system. This recognition marks a phased achievement of the enterprise in realizing green development under the background of high energy consumption.

At present, General Technology Shenyang Machine Tool has built 2 national-level green factories, 1 provincial-level green factory, and 1 provincial-level green supply chain management enterprise. Three of its products have been included in the provincial-level green design product list, and one unit has been awarded the title of "Waste-free Factory" at the municipal level. The selection of Shenyang Machine Tool Yinfeng Casting Co., Ltd. has further improved the company's green system covering the entire manufacturing chain.

Brands History:

With a long history and rich accumulation, SMTCL is one of the 156 key construction projects during the first Five-Year Plan period(1953--1957), creating a number of first projects in New China. During last decates, the company has always been adhering to the mission of providing equipments in China's industry, tracking the national demands, to achieve the continuous progress and breakthrough of domestic machine tool product technology, on the basis of widely improving the equipment level of China's small and medium-sized enterprises, develop and manufacture a number of high-level CNC machine tool products, to provide important equipment support for the national key industries and fields. In 2011, the sales volume became the first in the world machine tool industry, won the first China Industry Award, China's Top ten Innovative Enterprises, and other honors.

On December 20,2019, China General Technology Group company(Genertec) strategically restructured Shenyang Machine Tool(group) Co., Ltd (SMTCL) and become a backbone enterprise in the field of equipment manufacturing of Generteh, ushering in new development opportunities. Under the unified deployment of Genertec, SMTCL takes "new" specialization path of high quality development, focusing on the limit manufacturing, intelligent manufacturing, high-level manufacturing and efficient manufacturing, determined through unremitting efforts, greatly enhance independent innovation ability, efforts to make new breakthroughs in high-level CNC machine tool manufacturing, contributes to the revitalization of the Northeast old industrial base and the machine tool industry in China.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

What is an inverted vertical lathe?

The IVT45 inverted vertical lathe adopts a modular and systematic structural design, which is particularly suitable for medium and large batch processing. The inverted spindle structure and the large inclination Angle design of the bed protection ensure the smooth discharge of iron filings. The whole machine occupies a small area, ensuring lower space costs and the possibility of more machine tool layouts. Through centralized loading and unloading conveyor belts and diversified mechanical arms, future flexible production can be met, achieving lower automation costs and shorter equipment time. In addition, the machine tool can be optionally equipped with a Y-axis for processing complex geometric shapes and a measuring station outside the processing room, which enhances the flexibility of machine tool configuration. It is also equipped with a linear material line to support multiple machines.

Inverted Vertical Lathe IVT45 Spindle Gripping Automatic Loading and Unloading Vertical CNC Lathe

Advantage:Automated production: It can be combined with centralized loading and unloading conveying lines to form flexible automatic production lines, achieving large-scale production. One person can manage multiple devices, reducing labor costs.Small floor space: The whole machine has a compact structure and occupies a small area, which can effectively save factory space, reduce space costs, and is convenient for layout within the workshop.High precision: The machine tool bearings may adopt well-known brands such as SKF or FAG, and be paired with high-quality linear guides and ball screws to ensure the high stability and high precision of the machine tool.

Product Details:

Inverted spindle structure

Inverted spindle and large Angle protection design, chip removal effect is excellent; Optional power tool holder, to meet the milling, drilling, boring, tapping and other complex processing.

Feed line

Integrated automatic single feed line, with inverted spindle to achieve automatic feeding function, can choose linear feed line with multi-machine linkage automatic feed line, to achieve high precision, high efficiency, high automation processing unit.

Industry application:

It is applicable to industries such as automobiles, bearings, and petroleum, and can process parts like brake discs and bearing rings. The maximum processing diameter is 450mm.

Click the video to learn more about the products

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

What Is an Automated Production Line?

What Is an Automated Production Line?

In modern manufacturing, the automatic machine tool line (also called automated machine tool line) is a core production system that integrates multiple machine tools and automated devices. It realizes continuous, unmanned, or semi-unmanned processing of workpieces, which is widely used in industries such as automotive, aerospace, and electronics.

What Is an Automatic Machine Tool Line?

An automatic machine tool line is a modular production unit composed of multiple specialized machine tools (e.g., lathes, milling machines, drilling machines), material handling systems (e.g., robotic arms, conveyors), and central control systems.

Its core feature is to replace manual operations with automated equipment, completing the entire process from workpiece loading, processing, inspection to unloading in sequence. This system avoids human errors and ensures consistent processing quality while improving production efficiency.

We Have the Automatic Machine Tool Lines You Need, Ready for Supply!

Whether it’s mass processing or precision production, we offer both ready-to-ship and customizable high-efficiency automated machine tool lines you require.

Our equipment comes with CNC machining, intelligent logistics, and central control modules, enabling 24/7 unmanned operation. It boosts efficiency by over 30% and maintains a pass rate of over 99%. We provide end-to-end on-site services from selection to commissioning to help you start production quickly.

Scroll down to learn about equipment parameters, real cases, and cooperation plans immediately. You can also consult directly to get an industry-specific solution.

A625 New Energy Motor Shaft Automated Production Line Processing and Inspection Unit

Inverted Vertical Lathe IVT35 Automatic Workpiece Grasping Automated Production Line CNC Lathe

Multi-equipment Automated Production Line HTCSY50-S Automatic Production Line

Solution Introduction:

For workpieces with a longer processing cycle, one robotic arm can be used to load and unload materials for two machine tools, saving equipment procurement costs. For products that require U-turning processing, U-turning devices can be used to meet the requirements of automated processing. The solution integrates the machine tool and mechanical arm through a dual-channel CNC controller, ensuring stable operation. The automation uses full servo control, featuring fast operation speed, accurate positioning, and the ability to run 24 hours a day without the need for dedicated personnel to stand by.

Product Features:

- High efficiency: 24-hour operation, precise control of production capacity, effective increase in output, and cost reduction - High quality: Accurate positioning, effectively reducing the defect rate - Safe and reliable: Simple operation and reasonable protection

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Why choose Shenyang Machine Tool?

Shenyang Machine Tool: A Leading Force in China's Machine Tool Industry

Founded in 1993, Shenyang Machine Tool is a key national machine tool enterprise, born from three historic factories. It pioneered China’s first lathe, CNC machine tool, and smart i5 system-equipped machine.

After 2019’s restructuring with China General Technology Group, it focuses on high-end CNC machines like 5-axis centers and precision gantries, serving auto, aerospace, and energy sectors. With 12.8% R&D investment, it delivers global-level precision and solutions.

1、CNC Turning Center HTC40Hm Long-span Sleeve Spindle BMT55 Servo Power Turret CNC Turning Center With Y Axis

2、SMTCL VMC850Q 3 Axis Vertical Machining Center 4 Axis CNC Milling Machine With Turntable

3、SMTCL TK6513 Heavy Cutting High-rigidity CNC Horizontal Milling and Boring Machine

1. Forging Foundation: Strengthening Large-Scale Component Manufacturing

Technical Advantages: Adopts "step-type isothermal forging" and "integral forging-segmented quenching" processes. The hardness variation of 11-meter guideways is ≤ HRC ± 2, and the deformation resistance is 35% higher than that of traditional processes.

Capacity & Equipment: Equipped with 2,000-ton hydraulic die forging hammers and other equipment, capable of producing forgings weighing 0.5-50 tons. Annual capacity reaches 8,000 tons, with a qualification rate of key forgings ≥ 99.2%, realizing independent supply of large-scale forgings.

2. Processing Breakthrough: Full-Process Precision Control

1. Rough Machining: Efficient Shaping

For cast iron machine beds: Uses "layered milling + water spray cooling" with a daily processing volume of 15 m³ and an error of ± 0.5 mm; for alloy steel spindle boxes: Applies "high-speed milling + vibration aging" to eliminate internal stress.

Gear Branch: Has 217 sets of equipment, including 34 gear grinding machines for rough machining up to DIN3961-3 standard, with an annual output of 4 million gear forgings.

2. Precision Machining: Micron-Level Breakthrough

11-meter CNC guideway grinding machine + on-line inspection: The straightness error of guideways is ≤ 0.008 mm/m; radial runout of 8,000 rpm spindles is ≤ 0.002 mm.

Self-developed 5-axis machining centers: Achieve ± 0.005 mm precision for complex curved surface machining; 70% of equipment is localized. The GMC series has 15% higher efficiency and 30% lower cost than imported equipment.

3. Precision Testing: Comprehensive Strict Inspection

1. Component-Level Testing

Guideways: Inspected every 0.5 meters with laser interferometers; spindles: Underwent 24-hour continuous operation testing; Nano-grating displacement sensors: Realize 0.01 μm measurement, with better anti-interference performance than traditional gratings.

2. Machine-Level Testing

5-axis machines must pass the "S-test piece" international standard, with 200-point scanning; rework is required if the profile error exceeds 0.015 mm. The 7-meter gantry machining center launched in 2023 has a positioning accuracy of ± 0.01 mm, becoming a core equipment for "machine tool mother machines".

4. Equipment Commissioning: Customized Empowerment

System Efficiency: Three-level commissioning ("basic-process-capacity") reduces the cycle by 20% compared with the industry average; equipped with portable laser interferometers and other tools to complete on-site precision compensation.

Case Achievements: On-site commissioning for Jiangsu Pin'er's equipment increased efficiency by 30%; 72-hour full-load testing of 5-axis equipment further improved precision by 25% after parameter optimization.

5.Strong Customization Capability

1. Rapid Response: 72-Hour Demand Closure Loop

Respond to demands within 24 hours and break down core indicators in 3 hours;

Deliver initial solutions in 72 hours and optimize solutions in 48 hours, cutting the cycle by 50%.

2. Technical Adaptation: Full-Chain In-Depth Customization

Core components: Can increase spindle torque by 1.8x and extend guideways to 15 meters;

Process packages: Provide supporting dedicated fixtures and parameter databases, eliminating secondary debugging;

Software: Add new functional modules, achieving a precision of ±0.003mm.

3. Industry Application: Results in Key Scenarios

New Energy: Custom 5-axis machines with 8-ton workbench load capacity, 40% higher efficiency, and 2.5% lower defect rate;

Aerospace: 7-meter gantry machines, enabling one-time forming of rocket components with 100% precision;

Heavy Equipment: Boring and milling machines with 300mm spindle bore, 60% higher single-shift capacity.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

What is a floor boring and milling machine?

Floor-Type Boring Milling Machine is a heavy-duty and high-precision CNC processing equipment. Its core feature is the adoption of a floor-type stable structure. With boring and milling as its core functions, it also has the compound processing capabilities of drilling, reaming, tapping, etc. Designed specifically for large and heavy workpieces (such as machine tool beds, wind power flanges, box-type parts).

Its body is firmly connected to the ground, and the worktable can bear a load of tens to hundreds of tons. It is equipped with a movable spindle box and a multi-axis linkage system (commonly X/Y/Z/W/B axis), with a wide processing stroke coverage (the X axis often exceeds 10 meters). It has strong rigidity and excellent vibration resistance, and can complete multi-process precision processing of complex workpieces in one clamping. It is widely applied in heavy manufacturing fields such as construction machinery, ships, and energy equipment.

Why choose floor-type boring and milling machines?

Strong processing capacity for large and heavy workpieces: The floor-type boring and milling machine adopts a floor-type structure with a low center of gravity and a large contact area with the ground. It can bear the weight of workpieces weighing tens of tons or even hundreds of tons, making it suitable for processing large-sized workpieces such as large frames and boxes.

High precision: Equipped with high-precision numerical control systems, servo drive devices and precise transmission components such as ball screws and linear guides, it can achieve precise control of multi-axis linkage, ensuring the motion accuracy and repeat positioning accuracy of the machine tool. In addition, a good thermal stability design can also reduce the deformation of machine tools and further ensure processing accuracy.

Multi-functional compound processing: Integrating multiple processing techniques such as boring, milling, drilling, reaming, and tapping, it can complete multi-process processing of complex parts in a single clamping, reducing clamping errors and improving processing efficiency and quality.

Good stability: The overall structure is solid. The bed, column and other components are usually cast as a whole, with internal reinforcing ribs designed to withstand large cutting forces and vibrations. It remains stable during the processing, ensuring processing accuracy and surface quality.

In 1956, the China-Czech Friendship Factory developed China's first horizontal boring machine,

P-force Developed in the 1990 with cost-effective,stable performance and wide applications, well-trusted by customers.

High lights:

1、High cost performance, wide application range

2、For construction machinery industry, the double-sided layout (2 machines) as special purpose machine with high processing efficiency

3、X-axis heavy load linear guideway, Y-axis steel guideway for high rigidity and speed.

The floor boring and milling machine P-force of Shenyang Machine Tool has the following advantages:

Powerful transmission system: The X-axis adopts dual-motor dual-gear-rack drive technology, significantly enhancing the driving force. Its acceleration performance is better than that of the traditional single-motor dual-gear drive form. Through the control of the numerical control system, it can achieve reverse gapless transmission. The Y, Z and W axes are driven by high-rigidity preloaded ball screws to ensure the accuracy and stability of the movement of each axis.

High-rigidity ram structure: Equipped with a 480×480 square ram, it contains φ130 (φ160) mobile boring shafts, each with a stroke of 700mm. The four corners and eight sides of the ram are in contact, providing good rigidity and facilitating powerful cutting. Additionally, suitable accessory milling heads can be added to meet various processing requirements.

A wide processing range: The X-axis travel can reach 6000-20,000mm, the Y-axis travel has multiple specifications such as 2000mm, 2500mm, 3000mm, and 4000mm, the Z-axis (ram) travel is 700mm, and the W-axis (boring dry) travel is also 700mm, capable of processing large workpieces.

High power and large torque: The milling spindle power can reach 41-49kW, and the torque can reach 2900-3500Nm, which can provide powerful cutting power and is suitable for processing various materials.

Advanced numerical control system: It can be equipped with advanced numerical control systems such as Siemens and Fanuc to achieve precise position control and motion trajectory control, ensuring processing accuracy and efficiency.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

Good News: General Technology Shenyang Machine Tool has been successfully awarded the title of "National Outstanding Intelligent Factory"

Recently, the Ministry of Industry and Information Technology released the list of publicized projects for the "2025 Outstanding Intelligent Factory Project", and the "Intelligent Factory for Flexible Manufacturing of Machine Tools" of General Technology Shenyang Machine Tool was successfully selected. This is another national-level honor in the field of intelligent manufacturing that the company has received after being recognized as the only national 5G factory in the industry.

The company has been selected as one of the 274 national outstanding intelligent factories this time, and it is one of the 10 enterprises in Liaoning Province and 3 in Shenyang City that have been awarded. The national smart factory gradient cultivation is jointly promoted by six ministries and commissions including the Ministry of Industry and Information Technology. It is divided into four levels: basic level, advanced level, outstanding level and leading level, aiming to promote the digital transformation and intelligent upgrading of the manufacturing industry. Being awarded the title of National Outstanding Intelligent Factory indicates that the enterprise has reached the leading position in the industry in terms of intelligent manufacturing level and has achieved remarkable results in the application of artificial intelligence, system integration and value creation. At present, national leading intelligent factories are under cultivation.

Up to now, the company has built one national outstanding intelligent factory, three advanced intelligent factories in Liaoning Province, one benchmark demonstration enterprise for digital transformation in Liaoning Province, and one digital workshop in Liaoning Province, continuously demonstrating its leading position in the field of intelligent manufacturing.

Next, the company will deepen the application of the new generation of artificial intelligence technology, enhance efficiency through "intelligence", comprehensively promote the transformation from "manufacturing" to "intelligent manufacturing", and contribute to the transformation and upgrading of China's equipment manufacturing.

If you want to inquire about any SMTCL products, please contact us

E-mail: sales@huidijd.com

CNC Horizontal Boring Milling Machine: Top Efficiency & Precision for Heavy-Duty Machining

In the world of manufacturing, precision and efficiency are key. The PBC horizontal boring and milling machines by Shenyang Machine Tool Co., Ltd. are designed to meet these requirements, offering a wide range of features and capabilities for various industrial applications.

1. Product Overview

The PBC series horizontal boring and milling machines are high - end products independently developed and designed by Shenyang Machine Tool, combining market demands. These machines are known for their mature technology, stable quality, and advanced technical specifications, with software and hardware configurations at the international advanced level.

2. Structural Features

2.1 Guide rail system

The machine adopts a three - axis all - steel hard rail system. The rolling - sliding composite guide rail pair ensures stable operation, high precision, and strong rigidity. This design is especially suitable for heavy - duty cutting and high - precision machining tasks, reducing vibration and ensuring the accuracy of the machining process. For example, in the machining of large - scale engine blocks, the stable operation of the guide rail system can ensure that the machining accuracy of each hole and surface meets the strict requirements of the engine manufacturing industry.

2.2 Y-axis design

The Y - axis of the PBC series machines features a non - counterweight design. This allows for faster response of each component and smooth operation. The non - counterweight design reduces the inertia of the moving parts, enabling the machine to quickly start, stop, and change directions during the machining process. This is beneficial for improving the machining efficiency, especially when processing complex parts that require frequent changes in the machining path.

2.3 Boring Spindle Control

The boring spindle (W - axis) can be equipped with a magnetic scale for full - closed - loop control. This advanced control method ensures high - precision positioning of the boring shaft, improving the accuracy of hole - making and boring operations. In industries such as aerospace, where the precision requirements for parts are extremely high, the full - closed - loop control of the boring shaft can meet the strict dimensional tolerance requirements for parts such as aircraft engine casings.

3. Processing Capabilities

3.1 Multi-functional processing

These machines are capable of a variety of machining operations, including boring, milling, drilling, reaming, countersinking, and threading. They can handle different types of materials, such as steel, cast iron, aluminum alloy, and non - ferrous metals. For instance, in the production of construction machinery parts, the PBC machine can perform all these machining operations on large - sized cast iron parts, meeting the diverse processing requirements of the construction machinery industry.

3.2 Powerful cutting

With a strong axial resistance, the spindle of the PBC series can perform powerful cutting. This is achieved through a well - designed spindle structure and high - torque drive system. When processing large - scale workpieces in industries like energy and metallurgy, the machine can efficiently remove large amounts of material, reducing the processing time and improving production efficiency.

3.3 Multi-axis linkage

The PBC horizontal boring and milling machines support multi - axis linkage. For example, the X, Y, Z, B, and W axes can achieve any four - axis linkage. This enables the machining of complex - shaped parts, such as impellers in the power generation industry and mold cavities in the mold - making industry. The multi - axis linkage function expands the application scope of the machine and meets the increasing demand for high - precision and complex - shaped part machining in modern manufacturing.

4. Application Industries

The PBC horizontal boring and milling machines are widely used in various industries:

Transportation industry:In the manufacturing of vehicle engines and transmission components, the machine's high - precision machining capabilities ensure the quality and performance of these key parts.

Energy industry:For the production of power generation equipment such as turbines and generators, the PBC machine can accurately process large - sized parts, meeting the strict requirements for power equipment manufacturing.

Metallurgical industry:It is used for machining large - scale metallurgical machinery parts, helping to improve the production efficiency and product quality of the metallurgical industry.

Construction Machinery Industry:From the production of excavator parts to the manufacturing of loaders, the PBC machine can handle the processing of various large - sized and complex - shaped parts in the engineering machinery industry.

Pump and valve industry:In the production of high - pressure pumps and valves, the machine's precision machining ensures the tightness and reliability of these products.

Mold industry:It can be used to machine complex mold cavities, contributing to the high - quality production of molds.

5. Conclusion

The PBC horizontal boring and milling machines by Shenyang Machine Tool Co., Ltd. are powerful tools in the manufacturing industry. With their advanced structural design, excellent processing capabilities, and wide range of applications, they play an important role in improving production efficiency and product quality in various industries. Whether it is for small - batch, high - precision production or large - scale, mass - production tasks, the PBC series machines can meet the needs of modern manufacturing.

Please contact us if you want to get an inquiry and its details

E-mail: sales@huidijd.com

For product details, please click

What is a 5-axis tool grinding machine?

A five-axis tool grinding machine is a high-precision grinding machine controlled by a five-axis linkage numerical control system, specifically designed for grinding various precision tools (such as milling cutters, drill bits, taps, and special-shaped tools, etc.). Based on the traditional three axes (X, Y, and Z linear axis), it adds two rotational axes (usually A-axis and C-axis), achieving complex motion trajectory control of the tool in multi-dimensional space, thereby processing complex cutting edges, curved surfaces or irregular structures that are difficult to complete with traditional equipment.

The working principle of a five-axis tool grinding machine: How does five-axis linkage achieve precision machining?

Most traditional tool grinding machines are three-axis or four-axis, which can only achieve grinding at straight lines or simple angles. When dealing with tools with helical grooves and complex edge shapes, their precision is insufficient. The core of the five-axis tool grinding machine lies in "five-axis linkage" :

Three linear axes (X, Y, Z) control the linear displacement of the grinding wheel and the cutting tool.

Two rotating axes (such as the A-axis rotating the tool and the C-axis rotating the grinding wheel or worktable) adjust the relative Angle between the tool and the grinding wheel.

The numerical control system calculates and synchronously controls the five-axis movement in real time to ensure that the grinding wheel always contacts the tool surface at the optimal Angle and feed rate, achieving high-precision grinding of complex cutting edges and curved surfaces.

The core advantages of five-axis tool grinding machines: Why choose it?

Compared with ordinary grinding machines, the advantages of five-axis tool grinding machines directly address the pain points in precision tool processing:

1. Higher processing accuracy: Five-axis linkage reduces multiple clamping errors, with tool size accuracy reaching ±0.001mm and surface roughness as low as Ra0.02μm, meeting the demands of high-end fields such as aerospace and precision molds.

2. Compatible with complex cutting tools: It can process helical milling cutters, ball-end cutters, forming tools, non-standard special-shaped tools, etc., and is especially suitable for tools with three-dimensional curved surfaces or multiple cutting edges.

3. Combining efficiency and flexibility: Multiple processing procedures can be completed in one clamping, reducing tool changing time. Different tool models can be quickly switched through programming, adapting to small-batch and multi-variety production.

4. Stronger stability: The bed is mostly made of high-strength cast iron or granite, and is equipped with high-precision spindles and servo motors to ensure long-term operational accuracy.

Typical application fields of five-axis tool grinding machines

The high precision and flexibility of five-axis tool grinding machines make them "essential equipment" in the following industries:

1. Tool manufacturing industry: Producing standard tools such as milling cutters, drills, taps, reamers, etc., as well as non-standard tools for medical and aviation applications.

2. Aerospace: Specialized cutting tools for processing engine blades and special-shaped profile tools, meeting the grinding requirements of difficult-to-machine materials such as high-temperature alloys.

3. Automotive industry: Manufacturing high-precision gear cutting tools and mold edge cutting tools to enhance the processing efficiency of automotive parts.

4. Precision molds: The forming tools used for grinding the mold cavity to ensure the surface finish and dimensional accuracy of the mold.

Please contact us if you want to get an inquiry and its details

E-mail: sales@huidijd.com

For product details, please click

Multi-station Vertical honing machine: An outstanding tool in the field of precision machining

Multi-station Vertical honing machine: An outstanding tool in the field of precision machining

In modern manufacturing, precision processing technology is the core guarantee of product quality. Multi-station honing machines, as key equipment for precision processing, play a significant role in various industries due to their unique advantages.

1、Working Principle and Structural Design

The multi-station honing machine is based on honing technology. It achieves high-precision processing of inner holes, outer circles and other surfaces through the contact of the honing strip with the workpiece surface and the compound motion of rotation and reciprocation, which can optimize dimensional tolerances and surface quality.

Structurally, the vertical model is equipped with a rotary worktable and multiple workstations, each of which has an independent clamping and positioning device. The honing head can precisely adjust the rotational speed and feed rate, and coordinate the actions of each station through the numerical control system to achieve continuous and efficient processing.

2、Core Advantages

(1) High-precision processing

Adopting high-precision spindles and guide rail systems, combined with real-time numerical control control, the processing dimensional tolerance is extremely small, and the shape accuracy such as roundness and cylindricity is excellent. The surface roughness reaches Ra0.2-Ra1.6μm, meeting the requirements of precision parts.

(2) High-efficiency production capacity

The multi-station parallel processing design significantly enhances efficiency. For instance, a six-station model can complete the processing of six workpieces per minute. Equipped with an automatic loading and unloading device, it reduces loading and unloading time and is suitable for large-scale batch production.

(3) Wide adaptability

It can process various materials such as steel, aluminum alloy, and engineering plastics. Through parameter adjustment and tool replacement, it can adapt to the processing requirements of inner holes with different diameters and shapes, as well as planes and spheres, with flexible application scenarios.

3、Industry Application Scenarios

(1) Automobile manufacturing

It is used for processing key components such as engine blocks, cylinder liners, and connecting rod holes, optimizing surface accuracy to reduce friction, improve fuel economy, and ensure the quality of components such as transmissions and braking systems.

(II) Aerospace

Process high-precision components such as turbine blade tenon holes and combustion chamber nozzle holes, improve surface quality to withstand extreme working conditions, and ensure the connection accuracy and safety of aircraft structural components.

(3) Hydraulic and pneumatic fields

Honing of the oil cylinder, the inner hole of the cylinder and the hole system of valve components can improve the sealing performance and the smoothness of movement, reduce leakage and friction, and extend the service life of the hydraulic and pneumatic system.

4、 Technological Development Direction

(1) Intelligent upgrade

Integrating sensors and intelligent systems, it collects processing data in real time and automatically optimizes parameters, supports remote monitoring and fault diagnosis, and improves maintenance efficiency.

(2) Improvement in precision and efficiency

Optimize structural design and manufacturing processes to reduce thermal deformation; Improve the multi-station layout, increase the movement speed of the honing head, and achieve higher precision and efficiency.

(3) Green Manufacturing Transformation

By adopting energy-saving drive systems and environmentally friendly processes, the consumption of coolant is reduced, and degradable cutting fluids are developed to lower energy consumption and environmental pollution.

Multi-station honing machines, with their high precision, high efficiency and strong adaptability, have become core equipment for precision manufacturing. With the development of intelligence and greenness, it will continue to contribute to the high-quality upgrading of the manufacturing industry.

Please contact us if you want to get an inquiry and its details

E-mail: sales@huidijd.com

Click the link to view the video

Why choose GT Shenyang Machine Tool?

Brands History

Shenyang Machine Tool was established in December 1995 after the asset reorganization of the three original machine tool factories

Shenyang No. 1 machine tool works

First conventional lathe of China in 1949 First radial drilling machine of China in 1953

Shenyang Sino-Czech friendship works

First boring machine of China in 1956 First auto lathe of China in 1958

Shenyang No. 3 machine tool works

First CNC lathe of China in 1975 First metal emblem of China in 1951

Briefs

With a long history and rich accumulation, SMTCL is one of the 156 key construction projects during the first Five-Year Plan period(1953--1957), creating a number of first projects in New China. During last decates,the company has always been adhering to the mission of providing equipments in China's industry, tracking the national demands, to achieve the continuous progress and breakthrough of domestic machine tool product technology, on the basis of widely improving the equipment level of China's small and medium-sized enterprises, develop and manufacture a number of high-level CNC machine tool products, to provide important equipment support for the national key industries and fields. In 2011, the sales volume became the first in the world machine tool industry, won the first China

Industry Award, China's Top ten Innovative Enterprises, and other honors. On December 20,2019, China General Technology Group company(Genertec)strategically restructured Shenyang Machine Tool(group) Co., Ltd (SMTCL)and become a backbone enterprise in the field of equipment manufacturing of Generteh, ushering in new development opportunities. Under the unified deployment of Genertec, SMTCL takes "new" specialization path of high quality development, focusing on the limit manufacturing, intelligent manufacturing, high-level manufacturing and efficient manufacturing, determined through unremitting efforts, greatly enhance independent innovation ability, efforts to make new breakthroughs in high-level CNC machine tool manufacturing, contributes to the revitalization of the Northeast old industrial Base and the machine tool industry in China.

Product category

The main products include five categories, turning,milling, boring ,drilling and special machine, total 139 specifications.

We offers a full range of machines: lathes, drilling machines, intelligent machining centers, etc., covering multiple fields and meeting automotive, aerospace and other industry needs. Customized solutions available for special specs, processes and intelligent upgrades.

Welcome to contact us—we empowers your intelligent manufacturing!

comprehensive catalogue _En.pdf

What is a five-axis machining center?

5-Axis Machining Center: The Core Tool for Precision Manufacturing

5-axis machining center is a high-end CNC machine tool that enables 5-axis simultaneous machining by synchronously controlling three linear axes (X, Y, Z) and any two of the rotary axes (A, B, C—such as the A/C axis of the VMU63P). Its key advantages include:

Complex surface machining capability: Multi-angle cutting avoids tool interference, significantly improving precision and surface quality for parts like aerospace impellers and medical implants.

One-time clamping for full-process machining: Reduces repetitive positioning errors, shortening production cycles by over 30%, ideal for multi-step scenarios like mold and automotive parts manufacturing.

Shenyang Machine Tool VMU63P: A Model of High-Performance 5-Axis Machining Centers

1. Core Technical Parameters & Performance

High-speed dynamic response: X/Y/Z axes reach a rapid traverse speed of 60m/min with 1g acceleration; A/C axis, driven by torque motors directly, rotate at over 50r/min for high-precision, fast attitude adjustment.

High-precision stability: The bed and column use integral casting with artificial mineral cast stone, increasing vibration resistance by 40% and reducing thermal deformation by 30%. Paired with full-closed loop gratings, positioning accuracy reaches ±0.002mm.

Powerful configuration: Optional 20,000r/min high-speed electric spindle supports efficient machining of difficult-to-cut materials like titanium alloys and superalloys.

2. Industry Applications

Energy & molds: Precision milling of turbine blades and impellers, completing full-process machining (profiles, blade crowns, damping platforms) in one clamping with a yield rate over 99%.

Automotive manufacturing: For mass production of aluminum alloy subframes and motor housings, paired with dual pallet changers, boosting efficiency by 20%+.

Medical equipment: Nanoscale precision ensures safety of artificial joints, with surface roughness Ra≤0.1μm, meeting ISO 13485 medical standards.

3. Localized Tech Breakthroughs & User Value

Independent core components: Equipped with Shenyang Machine Tool’s self-developed Feiyang CNC system, replacing imported systems and cutting maintenance costs by 30%.

Smart integration: Supports CAM-CNC integrated programming, customizable process packages, and remote monitoring for real-time status tracking and fault alerts.

Cost-effectiveness: 25-30% lower price than imported equivalents, with localized support for 50% faster response.

Why Choose VMU63P?

Leading tech: Combines linear motor and torque motor direct drive, outperforming traditional gear transmission.

Proven reliability: 99.8% stability in 24/7 operation at clients like Hangtian Xinguang Group, with MTBF over 8,000 hours.

Eco-friendly: Energy-saving servos cut energy use by 15%, compliant with EU CE and domestic carbon neutrality policies.

Summary

With "high speed, high precision, high rigidity" and localized core tech, Shenyang Machine Tool VMU63P is ideal for complex part machining in energy, automotive, and medical sectors. Its smart solutions meet modern manufacturing’s demands for efficiency and precision, helping businesses reduce costs and boost competitiveness.

Why Choose a CNC Turning Automation Line?

In today's fiercely competitive manufacturing landscape with rising costs, finding efficient, stable, and cost-reducing production methods is crucial for business survival and growth. CNC Turning Automation Lines are becoming a strategic choice for more and more manufacturers. This isn't just an upgrade to a single machine; it's a revolution in the entire production model. Here are its core advantages:

1. Break Through Efficiency Bottlenecks, Surge Output:

* 24/7 Continuous Operation: Equipped with robots or gantry manipulators, the automation line handles automatic loading, machining, and unloading of workpieces, completely freeing up labor and enabling round-the-clock production.