Product Description:

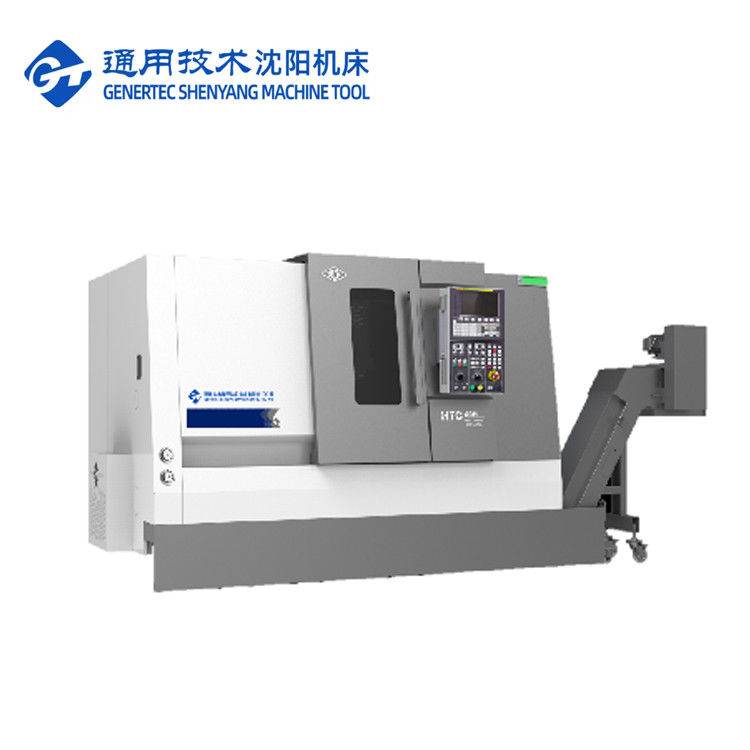

High Precision CNC Turning Center HTC40Hm Large Spindle Torque 178N.m Slant Bed CNC Lathe With Y Axis

HTC40Hm horizontal turning center has been assembled and improved through scientific analysis,optimization and advanced manufacturing and testing technologies. It has excellent cutting performance and can meet the processing requirements of various rotary parts. Equipped with a servo-driven turret, it can realize processing methods such as turning, milling and drilling. It can also be equipped with a servo-driven tailstock module. The tailstock can tightly abut at high speed without impact, and the abutting force can be intelligently adjusted. It features high machining accuracy and good stability, andis suitable for processing parts in many industries.

Product Features:

1,High Efficiency

- High-efficiency servo power tool holder

- Split servo tailstock

- High rapid movement speed of two axes

- Optional Y-axis configuration to achieve multi sequence integrated processing

2,High Precision

- High-precision pre-stretched screw

- Error compensation technology

- Quantification of process standards

- Strict inspection standards

3,High Rigidity

- Machine bed and other key castings made of high -quality cast iron

- Large span spindle unit

- Arc-shaped anti-bending saddle

- Small spindle structure tailstock

Product Details:

Rapid moving speed: 30m/min

The servo motor is directly connected to the ball screw through a coupling, reducing intermediate links and achieving gapless transmission. The X and Z-axis guide rails adopt imported linear rollingguide rails to ensure high rigidity, good dynamic performance and accuracy, increase operating speed and improve production efficiency.

Split Servo Tailstock

The tailstock can be moved in an optional servodriven manner, which can precisely control and flexibly adjust the tailstock moving speed and working clamping force according to processing requirements, allowing the tailstock to quickly approach the workpiece and tighten without impact , and can provide real-time feedback on the tightening position.improve production replacement efficiency. It adopts an upper and lower split tailstock ,easy to adjustment accuracy and improve maintenance efficiency.

Double fixed pre-tensioned structure

X axis develops a double fixed support structure and uses a pre-stretched screw to effectively offset pre-stretch deformation and temperature risedeformation. It cooperates with a special sealing structure to reduce the temperature rise of the screw, thereby achieving high precision and high precision of machine tool feed stability

Y axis configuration

Optional Y-axis configuration, combinedwith BMT powered turret, high-precision C -axis structure and a variety of poweredtool holders, can realize complex surface processing with once installation.

High precision ball screw

It uses high-quality imported C3-grade screw and H-grade guide rail, and is directly driven by servo motor to achieve excellent operating accuracy.

Anti-bending saddle

The guide rail span is reasonably enlarged,the motion system structure is optimized,and the main body of the bed saddle isdesigned in an arc shape to ensure theoverall rigidity of important components.

Efficient servo powered turret

Standard BMT interface, high rigidityconnection; the tool is driven by DIN1809 interface, which has reliable transmission and low failure rate;the drive motor is side-mounted and compact in structure; it is equipped with high-precision C axis and brake device to achieve high-efficiency integrated processing of turning, milling anddrilling.

Internal cooling tool holder

Optional internal cooling tool holder and water outlet from the tool center realize efficient chip removal during inner hole machining and ensure processing quality

Driven tool milling capability

Workpiece material: HT200

Tool model: Ф20 square shoulder milling cutter

Cooling status: water cooling

Driven tool drilling capacity

Workpiece material: HT200

Tool model: Ф16 twist drill

Cooling status: water cooling

Product Parameters:

| Project |

Unit |

HTC 40H(Q)m/500 |

HTC 40H(Q)m/1000 |

| Max. cutting dia. |

mm |

Φ350 |

Φ350 |

| Max.cutting length |

mm |

450 |

950 |

| Max. swiming dia.over bed |

mm |

Φ560 |

Φ560 |

| Max. swiming dia.on slide |

mm |

Φ350 |

Φ350 |

| Spindle |

|

|

|

| Spindle nose model |

|

A2-6 |

A2-6 |

| Front bearing inner dia. |

mm |

100 |

100 |

| Spindle taper and hole size |

|

1:20;Φ70 |

1:20;Φ70 |

| Dia. of spindle hole |

|

Φ65 |

Φ65 |

| Max.bar dia. |

mm |

Φ50 |

Φ50 |

| Spindle speed range |

r/min |

4500 |

4500 |

| Rated spindle torque |

N·m |

130(800r/min) |

130(800r/min) |

| Spindle Max. torque |

N·m |

230(600r/min) |

230(600r/min) |

| X/Z axis |

|

|

|

| X/Z axis rapid movement |

m/min |

30 |

30 |

| X axis travel |

mm |

220 |

220 |

| Z axis travel |

mm |

510 |

1000 |

| Tailstock |

|

|

|

| Tailstock travel |

mm |

500 |

500 |

| Tailstock drive method |

|

Hydraulic drive |

Hydraulic drive |

| Tailstock taper hole taper |

Morse |

MT-5 |

MT-5 |

| Turret |

|

|

|

| Turret typle |

|

Horizontal 12-station power turret |

Horizontal 12-station power turret |

| Center height |

mm |

100 |

100 |

| Turret indexing repeat positioning accuracy |

Sec. |

±1.6 |

±1.6 |

| Tool size |

mm |

25 |

25 |

| If could choose tool nearby |

|

yes |

yes |

| Power tool holder interface |

|

BMT55 |

BMT55 |

| Max. drilling capacity |

mm |

16×0.2 |

16×0.2 |

| Max. milling capacity |

mm |

14×10×40 |

14×10×40 |

| Max. tapping capacity |

mm |

M12×1.5 |

M12×1.5 |

| Others |

|

|

|

| Distance between spindle center and floor |

mm |

1050 |

1050 |

| Machine tool net weight |

kg |

4200 |

4750 |

|

Note: The parameters provided in the table are for reference only. If there is any change, please refer to the actual product.

Standard configuration:

- FANUC-0i-TF Plus (5) System (Hm/Sm Series)

- GSK988TA System (Qm Series)

- Sleeve-type spindle

- Hollow chuck oil cylinder

- Horizontal 12-station power tool carriage

|

OUR Service:

Ensure you receive a high quality machine

- Every parts need be inspected

- Over 100 production process control

- Over 200 inspection items

- Sample processing of each machine

- 72 hours trial run before delivery

Why Choose Us:

- Top quality sense, customers' requests come first

- 30 years + R & D history, the company was founded in 1993

- High-tech manufacturer with research anddesign capacity

- Stable and mature supplying system

- Young active sales and engineers for instant services(24 hours online)

- Upgrading on mechanism according to ergonomics and easy maintenance

- Our structure design principle: easy maintenance & installation, low cost maintenance, not affect production

About Us:

Welcome to visit us!

Shanghai HD M&E Tech Co., Ltd is located in Shanghai, China. We specialize in CNC lathe, vertical machining center, horizontal machining center, gantry machining center, five-axis machining center, turn-milling center and various other CNC equipment. We have more than 200 kinds of machine tools. The quality and technology of products have reached the international advanced level.

Our factory has over 80 years’ history of manufacturing machine tools. The first lathe, drilling machine and boring machine were all born here. They have been one of the leader of China's Machine Tool industry and the largest machine tool manufacture in China. Machine tool products cover automobiles, aviation, new energy, construction machinery, ships, pump valves, bearings, 3C electronics, molds and other industries. We take the mission of providing the machine tools with leading technology, high quality and good service to our customers all over the world!

Our Factory:

FAQ:

Q1. Are you a trade company or manufacturing company?

We are a manufacturing company.

Q2. What's your main products of your company?

We specialized in all kinds of machines, such as CNC Lathe, CNC Milling Machine, Vertical Machining Center,Conventional Lathe, Drilling Machine, Radial Drilling Machine, and so on.

Q3. Can you provide customized machine or SPM (Special purpose machine)?

Yes, we provide Smart CNC solutions for our customer in order to increase efficiency.

Q4: What's your warranty terms?

We will supply a replacement for parts that prove to be defective for a period of 12 months, starting on the machine's bill of lading date.

Q5. What is the services?

Pr-sales:Customized solutions, planning and design;One-to-one service

After sales:7 days 24 hours on line service, Remote guidance of installation, docking with customer software system

Q6: Why choose your company?

Products from the development, design, manufacture, assembly of the entire production process are carried out between plants with a complete production chain which is your most reliable guarantee.

Q7: Can your company send the technical personnel to our company and direct our workers overseas?

We can supply this kind of service. When the machines arrive the buyer's installation site, we can timely send mechanical and electrical engineers to install according to the buyer's schedule. All these can be quoted and list in the contract. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

Q8: What's the Payment Terms?

T/T 30% initial payment when order, 70% balance payment before shipment. irrevocable letter ofcredit at sight

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!